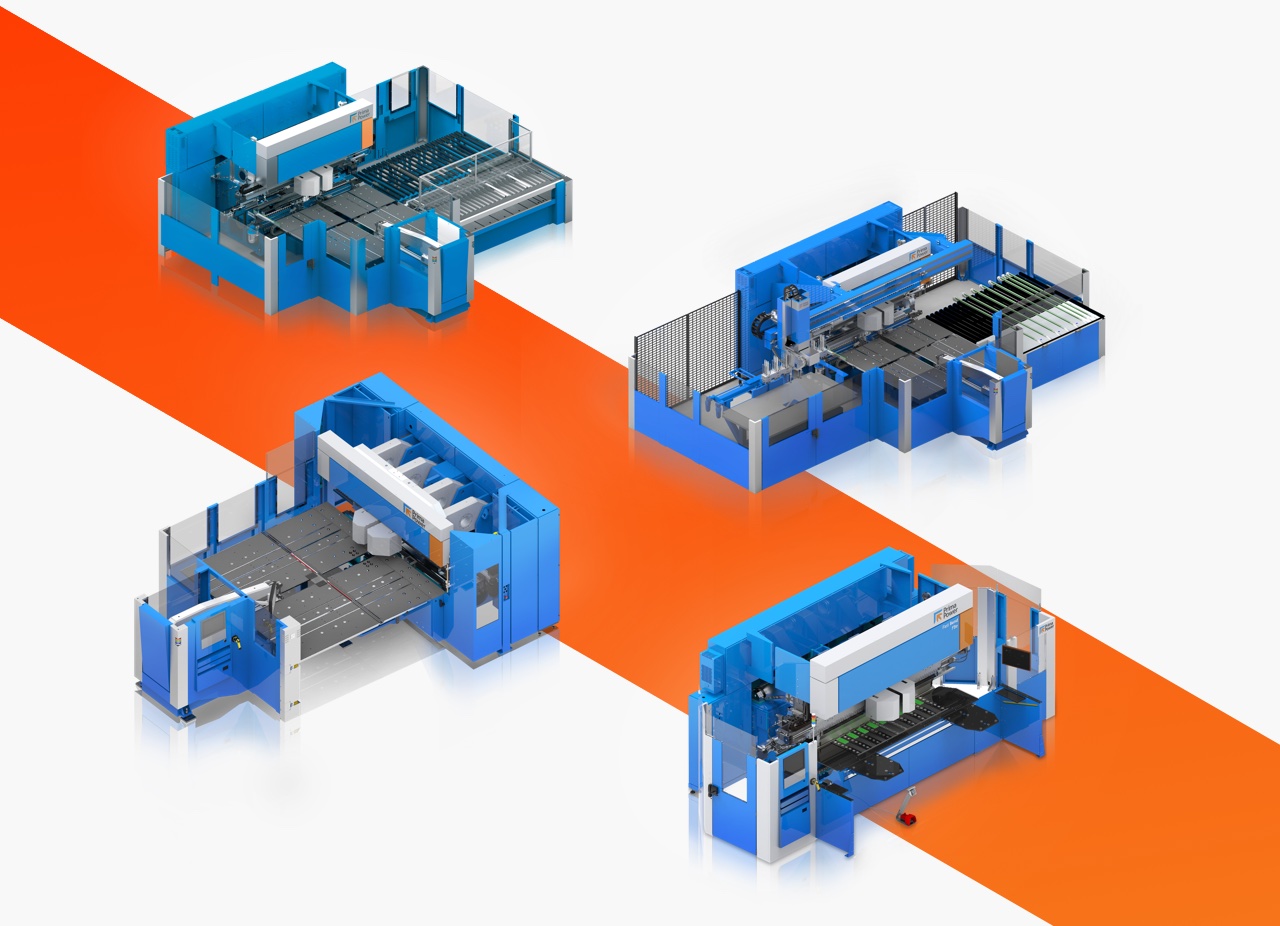

High efficiency Panel Benders product range

Prima Power provides advanced bending solutions for many manufacturing needs, using the state of the art of servo-electric technology. The result is more productivity and more efficiency.

For a quote, prices, insights and questions,

one of our experts is available to assist you.

Servo-electric

improves production.

All Prima Power Panel Benders are servo-electric: an energy saving, fast, accurate, non-hydraulic solution. This concept combines productivity, accuracy, flexibility and reliability with high respect for sustainability.

The Prima Power servo-electric machines advantages, compared to hydraulic solutions, are:

- 60% energy savings

- 70% maintenance cost savings

- 30% shorter production time

- Higher component quality

- Great accuracy and repeatability